Date: 10-95

Topic: No 4th Gear

Many Ford A4LD transmissions 3-4 shift complaints may be caused by a clogged 3-4 shift solenoid screen. An almost completely plugged screen can cause no 3-4 up-shift at all, while a partially restricted screen may cause 3-4-3 shift hunting, no 3-4 up-shift after 15 minutes of operation, or a 3-4 up-shift only at higher throttle openings (high line pressure).

Usually, the screen can be removed from the bushing to restore normal operation. However, a better option is to replace the 3-4 shift solenoid and screen assembly with the updated design.

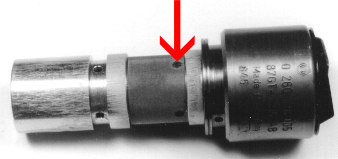

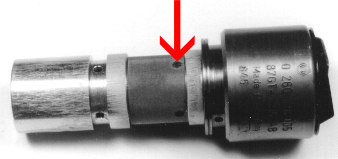

Trans solenoid A4LD

Part # E8TZ-7M107A which is the updated version of the solenoid is rather expensive to buy from the dealer at the manufacturers suggested cost of $236.88. So, a decision has to be made on which avenue to take. First off, lets assume the transmission has been checked out and you do not have to search for a rebuilt transmission. If that is the case then:

Popping the screen out of an old solenoid may be a short term cure because the solenoid is old and used. I’m all for going with the updated set-up, since I don’t like surprises like my transmission crapping on the way to Washington Redskins game. So, I would spend the extra ‘jack’ and buy the newer upgraded solenoid set. That goes almost unspoken for me, and it should be for you too.

There is a bigger issue underlying here. What clogged the screen in the solenoid?

That’s a very legitimate question, because unlike an internal combustion engine, where dirt is sucked in through the air filter as well as the contamination combustion produces, a transmission makes it’s own contamination, there is no internal combustion going on in a trans., so if the transmission shows contamination such as a silver metal-flake or gold metal-flake fine dust in the automatic transmission fluid, something inside the transmission is wearing out. If you do not fix the source of contamination and why the solenoid screen is plugged up, then essentially you are wasting money and spitting into the wind.

In short, something made of brass is wearing out if you see fine gold dust in the ATF automatic transmission fluid. As in, a silvery dust could be aluminum or steel, a magnet will help you decide, obviously ferrous metal will stick to a magnet. The point is that now you will need to remove, dismantle and inspect the transmission and decide if it is worth fixing or purchasing a rebuilt transmission.

In the end, most people find that an old transmission that is shedding its bushing or washer material may have, or be developing other issues. Which is why thinking of putting a rebuilt transmission in your car would give you the peace of mind, knowing that you won’t be experiencing any transmission problems for a long time. Good luck and Enjoy.